Vector Trailer Refrigeration Unit With Turbo

Engine Technology

Overview

Vector Trailer Refrigeration

Unit

Advanced Turbo Diesel

Engine

Vector With Turbo Diesel

Technology

Greater Power For Future Needs

Export Power

Fleets requesting power provided by Vector generator to be used for value-added, (non-refrigeration) functions

Natural Refrigerants

Low Global Warming Potential (GWP) refrigerants such as Carbon Dioxide (CO2) operate at higher pressures, requiring more power

Higher Capacity

Fleets pushing for longer, lighter weight trailers (i.e. less well-insulated) to improve freight efficiency

Higher Performance

In “intensive use” applications using auto start/stop, systems with higher performance will better control temperature while also reducing run time, emissions and overall costs

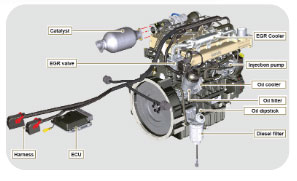

Engine Detail

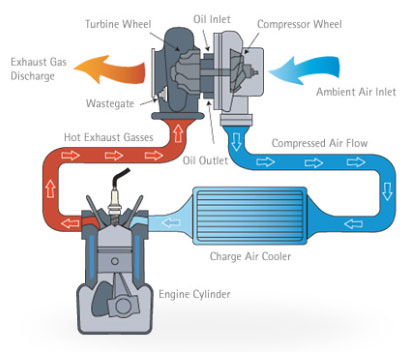

Turbo Benefits

Advanced Technology Engine

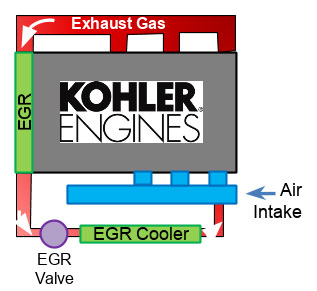

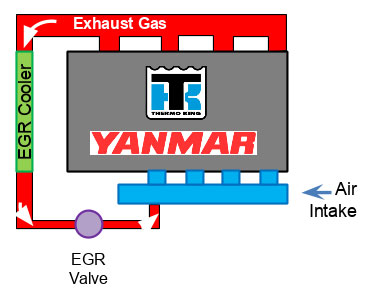

Differences in Vector Unit

[image_mapper id=”7″]

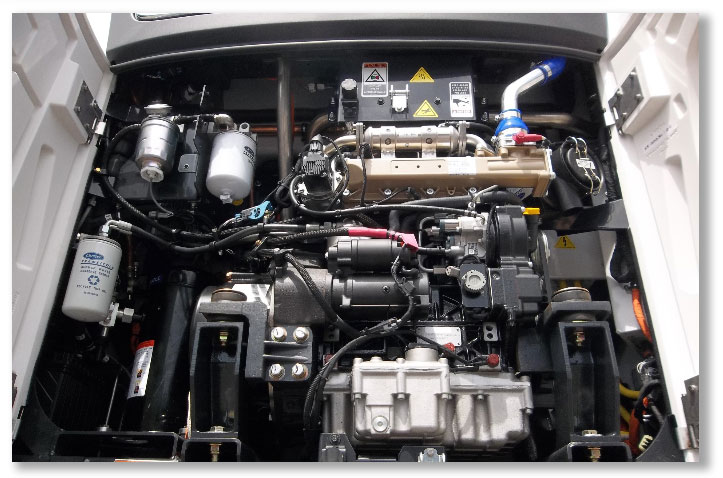

Vector Turbo Engine

Engine Comparison

| Greater Than 25 HP | Less Than 25 HP | ||||

| Carrier Kohler | Thermo King Yanmar | Thermo King Peugeot | Thermo King Yanmar | ||

| Displacement | 1.9 liter | 2.1 liter | 1.6 liter | 2.2 liter | 2.1 liter |

| # cylinders | 3 | 4 | 4 | 4 | 4 |

| Design type | Industrial | Industrial | Automotive | Automotive | Automotive |

| Timing Drive | Gear | Gear | Timing Belt | Gear | Gear |

| Head / Block construction | Cast Iron | Cast Iron | Aluminum | Cast Iron | Cast Iron |

| Fueling | 2000bar CR | 1600bar CR | 2000bar CR | Mechanical | Mechanical |

| High Speed RPM | 1,850 | 2,050 | 2,050 | 1,800 | 2,200 |

| EGR | Yes | Yes | Yes | No | No |

| Turbo | Yes | No | Yes | No | No |

| DOC | Yes | Yes | Yes | No | No |

| California >7 years | Yes | Yes | Yes | Yes with EES (DPF) | No DPF available |

Vector Performance Compare

| Standard Vector | Turbo Engine Vector | |||

| Cooling Capacity BTU/hr in 100°F ambient | Diesel Engine | Electric Standby | Diesel Engine | Electric Standby |

| 35°F setpoint | 60,000 | 60,000 | 59,000 | 60,000 |

| 0°F setpoint | 35,000 | 35,000 | 35,000 | 35,000 |

| -20°F setpoint | 24,000 | 24,000 | 24,000 | 24,000 |

| Fuel Efficiency | ||||

| Part load: 35°F setpoint, 75°F ambient continuous run operation | 0.51 GPH | n/a | 0.50 GPH | n/a |

| Part load: -10°F setpoint, 75°F ambient continuous run operation | 0.55 GPH | n/a | 0.52 GPH | n/a |

| Full load: 35°F setpoint, 100°F ambient continuous run operation | 1.10 GPH | n/a | 1.10 GPH | n/a |

| Full load: 0°F setpoint, 100°F ambient continuous run operation | 0.94 GPH | n/a | 0.97 GPH | n/a |